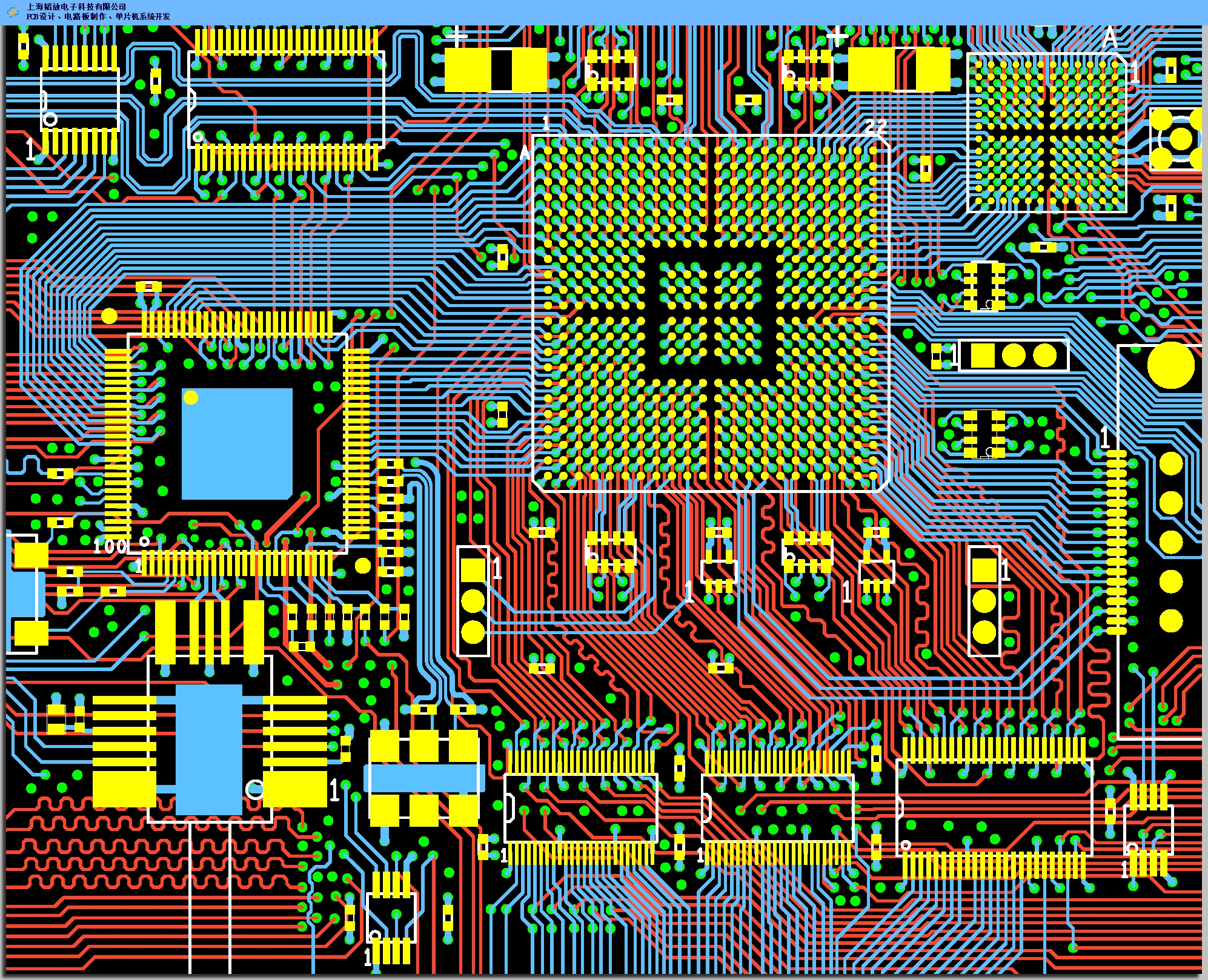

Comparison Between PCB Prototyping Service and Standard PCB Fabrication Service

Views : 8368

Update time : 2017-10-24 18:01:00

Comparison Between PCB Prototyping Service and Standard PCB Fabrication Service

| Item | PCB Prototype | Standard PCB |

| Application scope | Design review, prototype to quality testing | Full production |

| Quality Class Standards | IPC1 | IPC2 |

| Bonus service | / | Free DFM checking |

| Number of Layers | 1 - 8layers | 1 - 32layers |

| Order Quantity | 5pcs - 100pcs | 1pc - 10000+pcs |

| Build Time | 2days - 7days | 3days - 18days |

| Material | FR4 | FR4, Aluminum, Flex,Roges, etc |

| Board Size | Min 10mm x 10mm Max 500mm x 500mm | Min 6mm x 6mm Max 600mm x 700mm |

| Board Thickness | 0.4mm - 2.0mm | 0.4mm - 3.2mm |

| Copper Weight (Finished) | 1.0oz - 2.0oz | 0.5oz - 6.0oz |

| Min Tracing/Spacing | 5mil/5mil | 3mil/3mil |

| Min Annular Ring | 5mil | 3mil |

| Min Drilling Hole Diameter | 8mil | 6mil, 4mil - laser drill |

| Min Spacing Trace to Pad | 5.5mil | 4mil |

| Min Spacing Trace to Copper | 6mil | 6mil |

| Soldermask Sides | As per the file | As per the file |

| Soldermask Color | Green, White, Blue, Black, Red, Yellow | LPI, Green, White, Blue, Black, Red, Yellow |

| Silkscreen Sides | As per the file | As per the file |

| Silkscreen Color | White, Black | White, Blue, Black, Red, Yellow |

| Surface Finish | HASL ENIG - Electroless Nickle/Immersion Gold - RoHS | HASL ENIG - Electroless Nickle/Immersion Gold - RoHS ENEPIG - Electroless Nickel Electroless Palladium Immersion Gold - RoHS Immersion Silver - RoHS Immersion Tin - RoHS OSP -Organic Solderability Preservatives - RoHS |

| PCB thickness tolerance | ±0.1mm - ±10% | ±0.1mm - ±10% |

| PCB size tolerance | ±0.1mm - ±0.3mm | ±0.1mm - ±0.3mm |

| PTH hole size tolerance | ±0.08mm - ±0.15mm | ±0.08mm - ±0.15mm |

| Impedance control | / | ±5% - ±10% |

| Gold fingers | / | Yes, chamfer at 20, 30, 45, 60 |

| UL marking/Date code marking | / | Yes |

| Buried/Blind vias | / | Yes |

| Peelable solder mask | / | Yes |

| Edge plating | / | Yes |

| Carbon Mask | / | Yes |

| Kapton tape | / | Yes |

| Countersink/counterbore hole | / | Yes |

| Half-cutted/Castellated hole | / | Yes |

| Press fit hole | / | Yes |

| Via in pad | / | Yes |

| V-scoring limitation | 60*60mm | 25*25mm |

| Solder-stop coating bridge | / | Yes |

There are different Quality Class Standards in the industry. Most commonly followed is class 1 & 2.

Class 1 is for General Electronic Products and for testing and verification of Designs.

Class 2 is for Dedicated Service Electronic Products such as communication equipment,sophisticated business machines, instruments where high performance and extended life is required and for which uninterrupted service is desired.

Class 3 products are used in certain types of medical, aeronautics, and military applications for which uninterrupted and high reliability service is required.

相关新闻

中国印刷电路板的内资时代

中国印刷电路板的内资时代

Aug .02.2018

短期来看,覆铜板行业处于提价周期,下游需求景气推动公司单季度利润率上行。中长期看,PCB行业配套倒逼上游内资厂商扩产,2020年PCB上市公司资本开支同比增速重回到高位,对覆铜板厂商的配套诉求加剧,推动覆铜板厂商话语权提升,内资企业开启了一个新时代。

一些常常引起争议的PCB布线经验法则

一些常常引起争议的PCB布线经验法则

Aug .02.2018

如今,我仍然还能看到一些在20年前就常见的PCB布线的经验法则,它们现在还被广泛遵守和适用吗? 确切的答案是“也许吧”。一些关于PCB设计论坛中的遵守/避免布线法则,使得PCB设计者在这些规则也许不适用的地方要么遵守,要么忽略他们。一些情况下,这未必造成电路板设计失败。正像一些有经验PCB设计者所说,电路板是出于偶然的机会恰好可以正常工作。

电池线路板厂如何减少高频PCB电路布线串扰问题

电池线路板厂如何减少高频PCB电路布线串扰问题

Aug .02.2018

由于高频信号是以电磁波的形式沿着传输线传输的,信号线会起到天线的作用,电磁场的能量会在传输线的周围发射,信号之间由于电磁场的相互耦合而产生不期望的噪声信号称为串扰。

为了减少高频信号的串扰,电池线路板厂在布线的时候要求尽可能的做到:

解说2021慕尼黑华南电子展及华南电路板国际贸易采购博览会

解说2021慕尼黑华南电子展及华南电路板国际贸易采购博览会

Aug .02.2018

说到高频电路布线,电池线路板厂的PCB工程师比较头疼的,恐怕是高频信号的串扰问题。那么,电池线路板厂如何减少高频PCB电路布线串扰问题呢?

由于高频信号是以电磁波的形式沿着传输线传输的,信号线会起到天线的作用,电磁场的能量会在传输线的周围发射,信号之间由于电磁场的相互耦合而产生不期望的噪声信号称为串扰。